The GreenConcrete LCA Web version is based on an MS-Excel tool developed to analyze environmental impacts of production of concrete and its constituents (such as cement, aggregates, admixtures, and supplementary cementitious materials). The tool is not a conventional database of inventory of resources (materials, energy, and water) and some emissions from manufacturing concrete that only considers direct impacts, e.g. only tailpipe emissions during transportation of concrete materials or emissions from electricity generation. In GreenConcrete, the supply chain impacts of each process during the production of concrete and its materials are evaluated. For example, the transportation section calculates not only tailpipe emissions during transporting materials to concrete plant but also life-cycle phases of vehicles, infrastructure, and fuels are accounted based on literature on freight transportation. Similarly, when a process involves use of electricity, the tool provides not only direct electricity generation impacts but also supply-chain impacts that encompass the construction and operation of a power plant, as well as the life-cycle impacts of the most important resources used in the construction of the plant, the operation of the plant and so on.

The GreenConcrete LCA tool is specifically designed for cement and concrete manufacturers for the purpose of quantifying and comparing environmental impacts of their products. Decision makers in the construction sector including construction managers, contractors, civil engineers, architects and owners can also make use of the output of the GreenConcrete as a decision support tool for the selection of materials or concrete mixes based on their calculated environmental impacts.

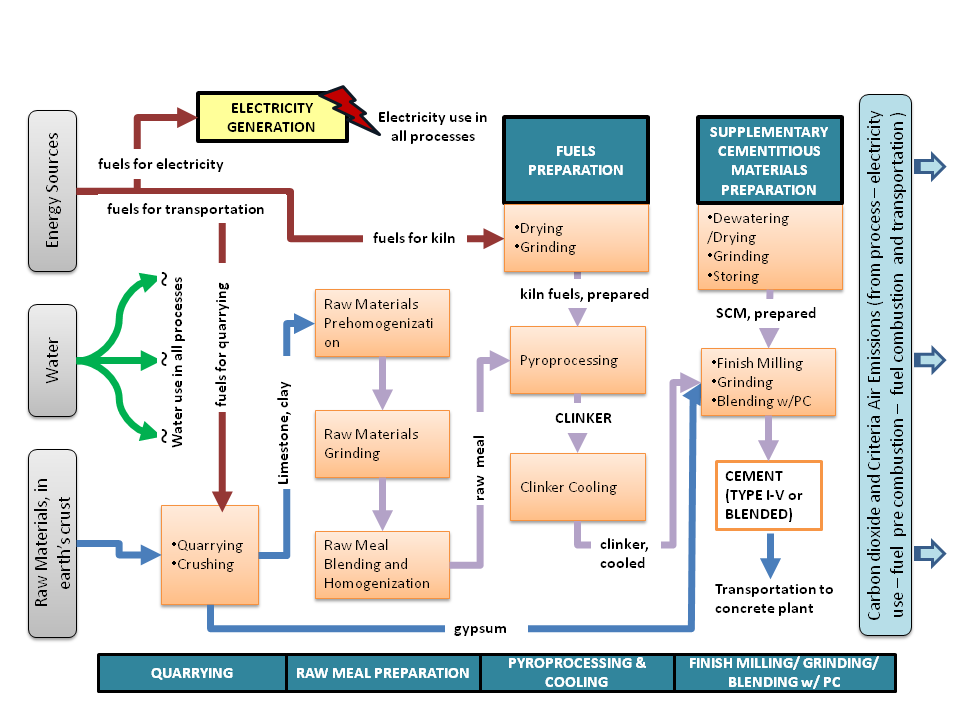

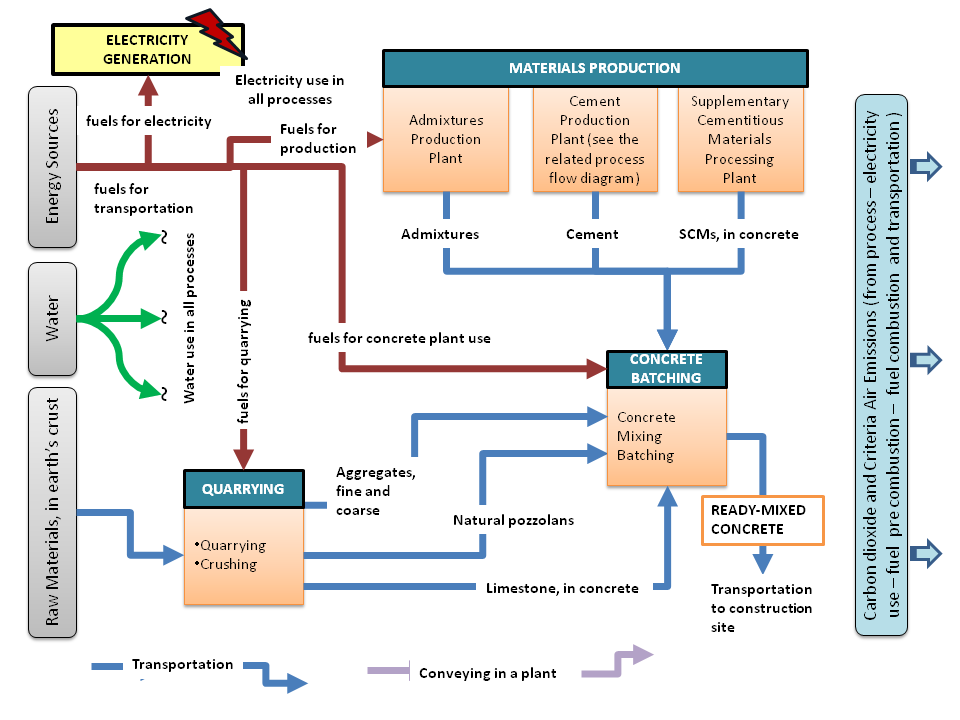

The functional unit defined in the tool is the unit volume of ready-mixed concrete exiting the concreteplant gate. The scope of the analysis encompasses environmental impacts associated with several different processes such as: raw materials (limestone, gypsum, natural pozzolan) quarrying and cement production, fine aggregates and coarse aggregates quarrying and processing, processing of supplementary cementitious materials (SCMs) such as fly ash and granulated blast furnance slag (GBFS), production of chemical admixtures, fuel use (pre-combustion and combustion- related) and electricity generation impacts associated with the processes considered and transportation of selected materials within the system. See Figure 1 and Figure 2 for the scope of the analysis.

_____________________________________________________________________________________________________________________________________

For further information contact Petek Gursel at pgursel[at]berkeley.edu

HTML and Javascript Coding by Claudine Custodio